DiZNEW Years

20 years garment production experience

the supplier can handle large-volume orders and small orders that have at least

Minor customization refers to custom logos, packaging, or graphics

The supplier supports customization based on design drawings

The supplier supports customization based on samples

The supplier supports customization based on specific requirement descriptions

20 years garment production experience

4000 square meters of factory

Approx 100 sets of Machine

Denim Jeans,Denim jacket,Denim shirt, Denim shorts

Good at men jeans development

Develop 600 styles new design per month

50K pcs/per month

Produced 300 styles bulk orders one monthe

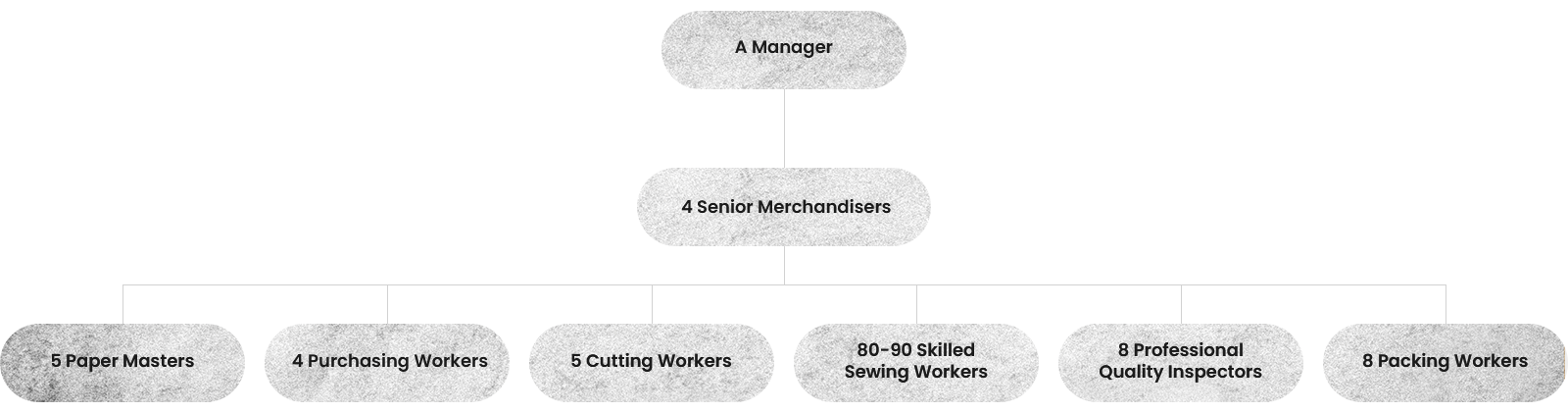

100+ worker

A 10-person team crafts denim prototypes

We have a U.S. team member for local support

01

01we offer a selection of fabrics based on your washing requirements.

02

02Based on the design drawings you provide or those created by our designers, we will make paper patterns.

03

03Purchase raw materials according to orders. We select high-quality, environmentally friendly and compliant materials.

04

04Cut fabrics according to paper patterns and sort and organize fabrics.

05

05Print, embroider or emboss your pieces. Apply design elements precisely to fabric.

06

06Sewing is done according to order requirements, using high quality sewing machines and threads to ensure the quality and appearance of the jeans.

07

07Wash the jeans using your specified wash process to ensure they match the look and feel you want.

08

08Strictly check the jeans' pattern, size, craftsmanship, fabrics, accessories, etc. to ensure they meet the requirements.

09

09Iron the jeans to ensure they are smooth and perfect.

10

10Packed as per your request and shipped to you in perfect condition.

Supports buyers in quality traceability

The supplier conducts stringent inspections on all its finished products

Number of supplier's QA/QC inspection employees

The supplier has a relevant inspection process for this product's raw materials

Supports buyers in quality traceability

The supplier provides quality assurance services

Our suppliers encompass fabrics, accessories, process assistance, packaging, transportation, and more.

We build long-term, stable partnerships with high-quality suppliers. Regular evaluations and performance monitoring ensure their quality pricing, and services align with our standards.

We ensure efficient operations and timely production line deliveries through meticulous planning and scheduling.

Each order is scheduled and monitored in detail to ensure timel completion of all processes, optimizing production line efficiency.

We develop long-term cooperative relationships with logistics partners to meet our service and transportation speed requirements.

We closely monitor the transportation status of goods, ensuring their safe and prompt delivery to customers.

We strategically plan raw material and component inventory to avoid excessive stock, reduce costs, and maintain inventory accuracy and transparency.

We use information technology and software systems to manage the entire supply chain, tracking and monitoring each link in real time, allowing us to quickly handle abnormal situations and ensure efficient operations and supply chain optimization.

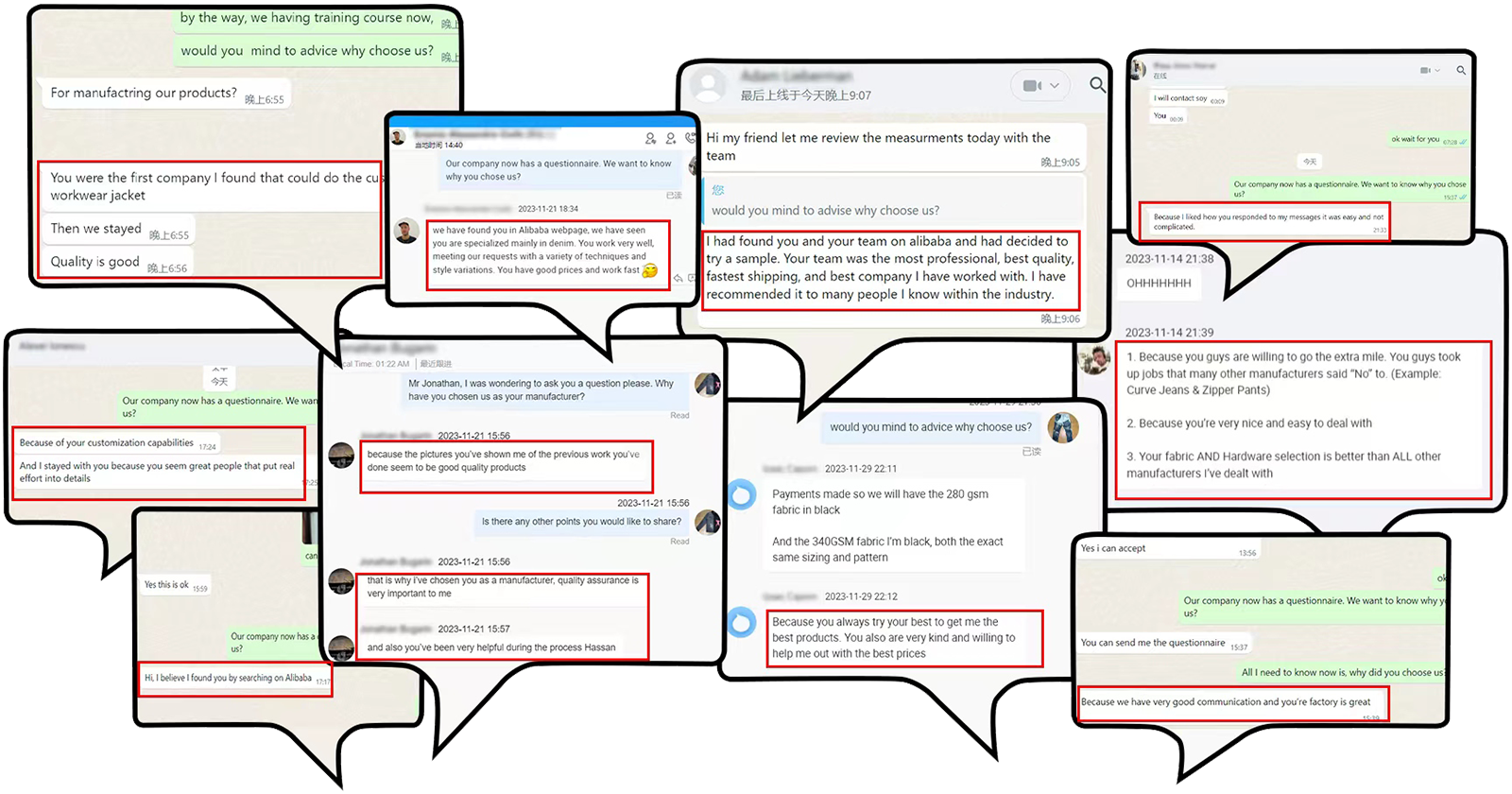

We pay attention to the growth of your clothing brand and make your brand more popular with users. DiZNEW's one-stop customization service can perfectly meet your clothing brand customization needs.

We have a first-class design team and controllable quality, we can launch new designs every month, from clothing fabrics to styles, we have excellent supply chain solutions, contact us now and start from a sample order to know our perfect Serve.

+86-13058567994